Salient pole rotor

The salient pole rotor has a lot of exposed poles positioned on a wheel of magnetism. The illustration on the left illustrates how a brilliant pole is built. Metal laminations are used to make the planned poles. These poles are equipped with rotor winding and supported with pole shoes.

Structure

The axial length and width of pole rotors are also significant. They are typically employed in low-speed electric machinery, such as those that rotation at 100 to 1500 revolutions per minute (RPM). Due to the low rotor speed, more poles are required to achieve the desired frequency. There are typically between 4 to 60 sharp pole generators.

The created emf (electromotive force) waveforms are inferior to a cylindrical rotor due to the poor flux distribution versus a non-uniform salient pole rotor. Pole rotors typically need winding dampers to stop the rotor from rotating while operating.

Objectives

- Use of starting circuits

- Safety precautions and electrical safety

- Building and commissioning of power systems

- Machine effectiveness

- Evaluation of electrical machine characteristic curves

Generator operation characteristics

Power generation is the primary area in which the synchronous motor is used. In drive control, it is also employed as a commutated synchronous machine. The commutated synchronized device has recently been deployed in e-mobility, whereby field control is used in addition to speed control. The synchronous generator has many applications, including colossal power plant generators, ship shaft generators, and automobile alternators. Different load types, startup, excitation, and efficiency are explored. The issue of power plant control, which is covered in greater detail in the study of electrical power engineering, is equally intriguing in this context. Hydroelectric power plants and diesel generators are the primary applications for salient pole generators.

Highlights

The different equipment can be used for teacher demonstrations or student experimentation in the lab using a low voltage (230/400 V three-phase current). The manual is followed for doing the experiments.

Students studying electrical machine construction and apprentices in the business world make up the target group. The course provides experiments at a middle stage and the undergraduate level with the requisite understanding of machine behavior for scientific interpretation. The experiments can be demonstrated in a lecture hall or classroom due to the media connection.

Read More: Why medical coding is a must-have in any medical practice

Salient pole rotor operating theory

A revolving magnetic flow is produced by a three-phase input machine’s stator windings thanks to the alternating current fed to them. The flux introduces a voltage that generates energy into electrical energy through the rotor conductors and creates magnetism in the space between the stator and the rotor.

Current is flowing to the rotor windings because the rotor circuits are short. Torque is produced to ignite the engine by the motion of revolving flux and steel.

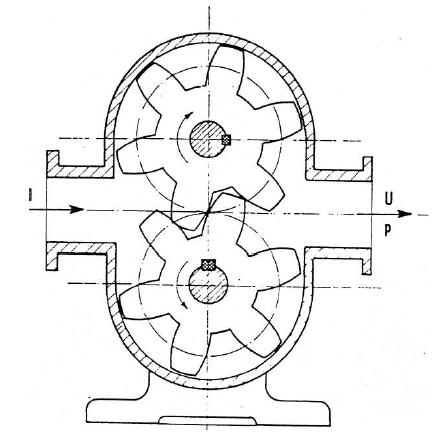

Internal structure

The wire coil that forms the generator rotor is encased in a metal core. To aid in form and size-seal the driver’s spaces, the magnetic portion of the rotor is constructed of stainless steel. A magnetic field known as the current domain is produced around the core as the currents flow through the wire coil. The field’s current strength controls the magnetic field’s energy level. Direct current (DC) is used to provide the existing area to the phone coil in a single direction using a set of brushes & smoothing rings.

Role of magnetic field

The magnetic field created by the pole runs north and south, much like any magnet. A rotor-powered engine’s regular clock direction can be changed using magnets & magnetic fields incorporated into the rotor’s design, enabling the engine to run backward and counterclockwise.

Very obvious pole synchronous generator

With the field poles’ construction features functioning through a sizable interpolar wind gap, the salient pole synchronous motor is divided by a circular saw blade. The salient pole generation system contains several pairs of various poles in machines connected to elevated steam engines (3,000/1,500 rpm) or two or four-pole constructions. This construction is frequently employed in devices connected to low-speed hydraulic power engines.

With the binary reaction answers, an analysis of the critical pole synchronous machine is carried out.

Axis of machine

In a circular rotors machine, the armature provides the same fluxes connection per ampere as long as the air gap is constant, which ensures that the armature reaction is delivered in the same category or quadrature current. The air gap and rotor perimeter are different in a pole machine. It is the greatest near the interpolar area axis and extremely little near the vertical axis of the central poles (called the quadrature axis).

The machine creates a higher armature response known as direct axis length reactance (Xd) in the quad Id phase flowing of armature current Ia when the armature current is in the quadrature with such a force that causes oscillations near the vertical axis or doubts of flow (owing to a tiny air gap).

Conversely, the armature current in sync with force results in modest flux connections per ampere due to variations near the quadrature axis and the flux route to the surface (caused by the significant interpolar air gap).

Consequently, the device generates a tiny arms response, denoted by the symbol Xq (quadrature axis length reactance Xd), in the period of armature current flow (Ia).

Operating a synchronous generator with prominent poles

The circuitry model cannot be generated because the virtual beams machine responds differently to the motion of the current arm’s component elements. The best stator & rotor current flow should be considered when selecting a large generator since they affect mechanical strain and temperature rise in addition to the small gigantic ampere and power factor. Spreadsheets or worksheets impose these employment limitations.

The impacts of space-filling, durability, intensity and resistance are disregarded for convenience of analysis, and only a small number of concurrent answers are taken into account. Turbines and other prominent pole synchronous generators are frequently employed in power plants.